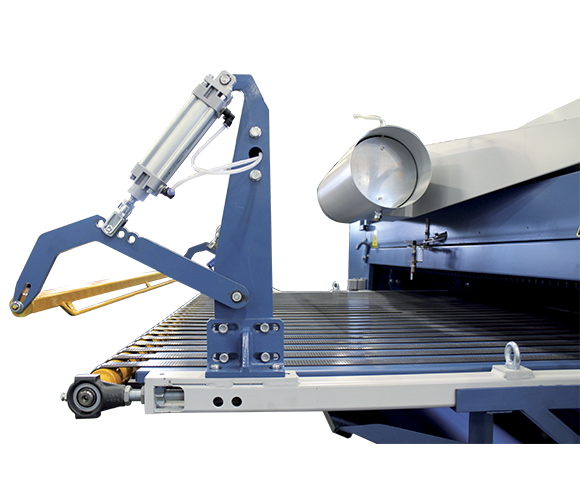

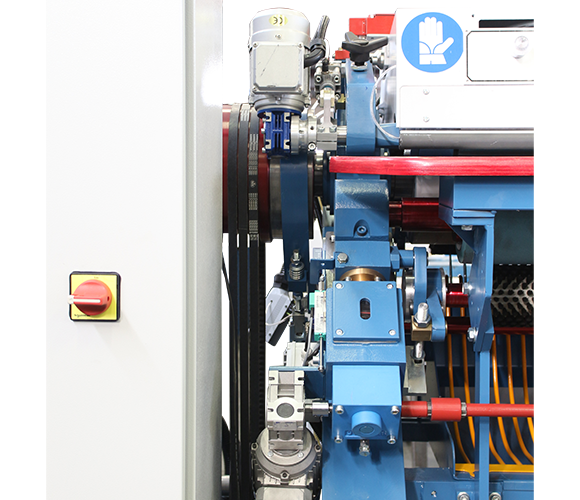

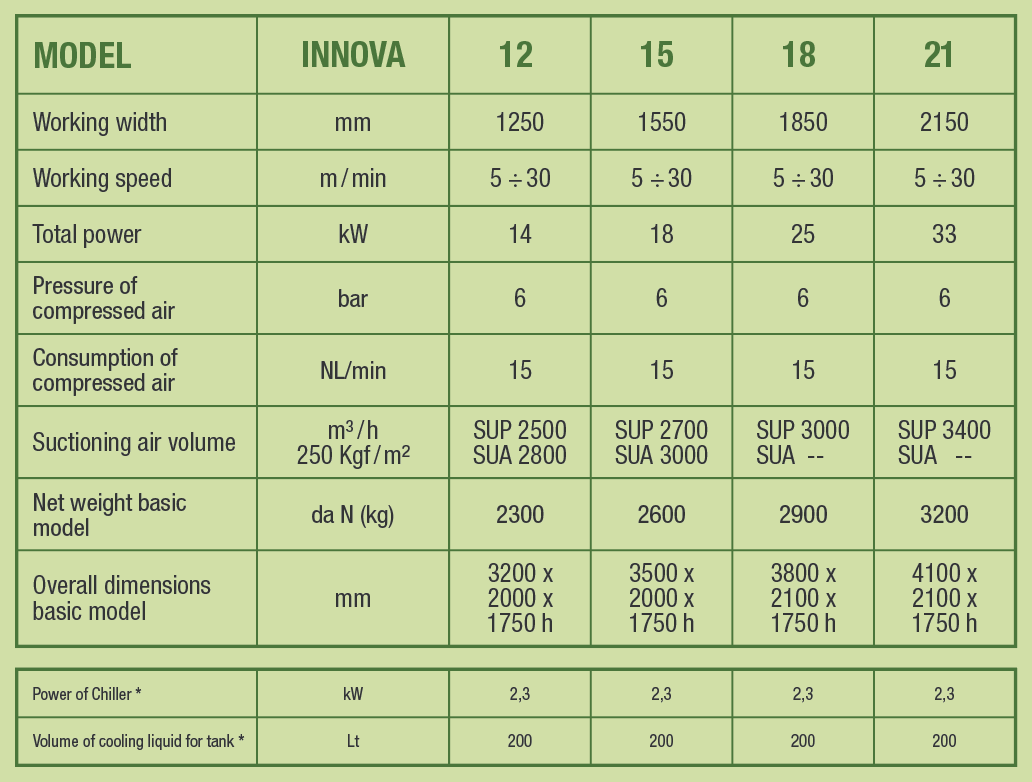

Through-feed roller buffing machine for 45° processing, suitable for soft leathers.

The different inclination compared to the traditional Selecta, which works at 90°, makes it possible to halve the distance between the buffing point and the exit belt, ensuring the leather is laid out more flatly at the entrance of the dedusting machine.