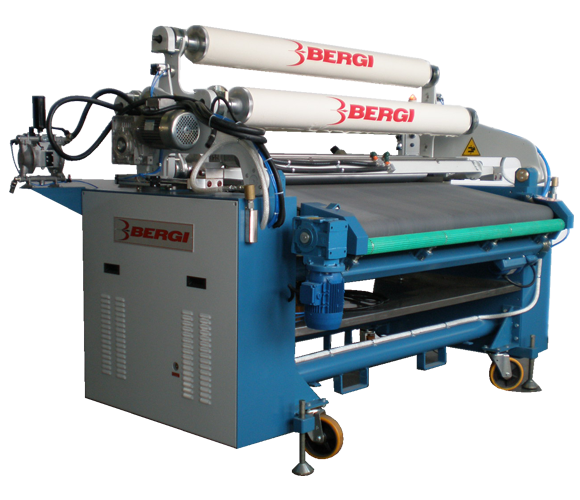

Totally redesigned, the Multicoat is the result of experiences matured on the field of coating applications since 1985.

In the development of this new model we have worked to obtain a machine easy to use and very versatile to help the operator in the various working stages.

The wide opening of the doctor blade to ease the cleaning operation of the operative roller, easily extractable washing tanks, independent adjustment of the thickness on left and right sides are only a few of the technical features if that characterize this machine.

Roller Coating Machine

MULTICOAT

Traditional roller coating machine

The Multicoat can be equipped with many accessories as it can be seen from the following list. The choice of the accessories depends on the type of article you are going to make. For any question of suggestion BERGI staff is available to help. The Multicoat machine is suitable to process many kinds of leathers and articles except for the very soft and empty leathers.

- Stucco and pre-base in “reverse”: Stucco pump, mixer, “HSS” roller

- Base coat e top coat in “reverse”: Standard equipment and “reverse” roller

- Oil: heating system, L-Type Synchro roller or Reverse type ones

- Wax: heating system, heated pump, heating tank and L-type synchro roller or reverse type ones

- Patent solvent: Mixer and HSC reverse roller

- Multipoint: Synchro doctor blade and “L-type” synchro roller

- Sturdy steel frame, laser shaped and fully welded;

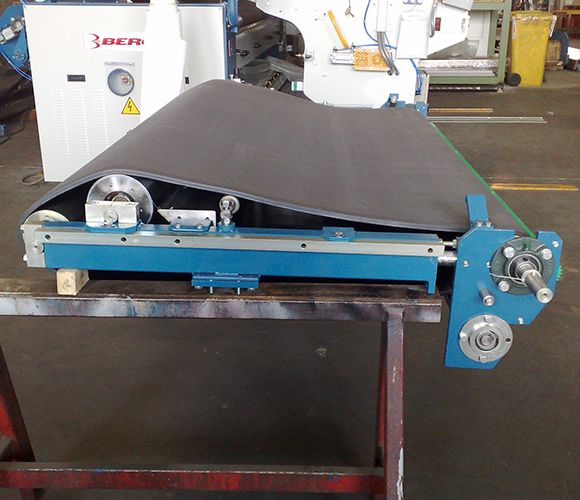

- Fixed transport conveyor with extractable structure;

- Rotating roller changing device available with a bridge with 2, 3 or 4 positions;

- Reverse roller pyramidal-truncated type for base coat, oil applications etc…;

- Motorized adjustment of the working thickness with independent setting on left and right sides;

- Double membrane colour pump

- Fixed colour distributor installed on the reverse doctor blade;

- Reverse doctor blade washing system by air and water jets;

- Recirculation tanks in stainless steel;

- Stainless steel washing tank easy to open and remove;

- Conveyor scraper with variable pressure to control humidity level;

- Internal conveyor scraper and waste collection tank;

- Pneumatic closing of the reverse doctor blade with mechanical fine tuning (pre-load);

- Motors controlled by inverter;

- Load compensation device (patented) with gap recovery device;

- Analogic control panel;

- Adjustable support roller to modify the geometry of the rubber transport conveyor;ù

- Big diameter wheels and adjustable supports

- Reverse helical roller “HSS type” for stucco application;

- Synchro “L-Type” rollers for tipping and oil applications in synchro;

- Design roller (at customer’s choice)

- Roller heating system with adjustable temperature;

- Heated tank for oil and paraffins with adjustable temperature;

- Piston pump for stucco and base coats with larger delivery pipes;

- Pre-heated piston pump for oils and paraffins;

- Mixer/distributor installed onto the reverse doctor blade;

- Synchro doctor blade with manual fine-adjustment (pre-load);

- Double feeding conveyor with adjustable speed;

- Leather detaching device at the end of the rubber conveyor with ABS system