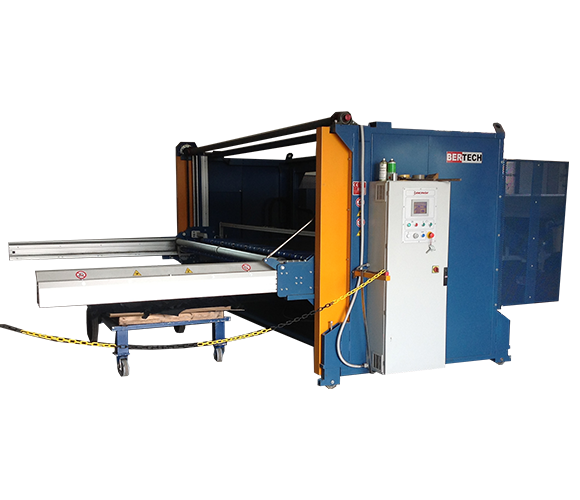

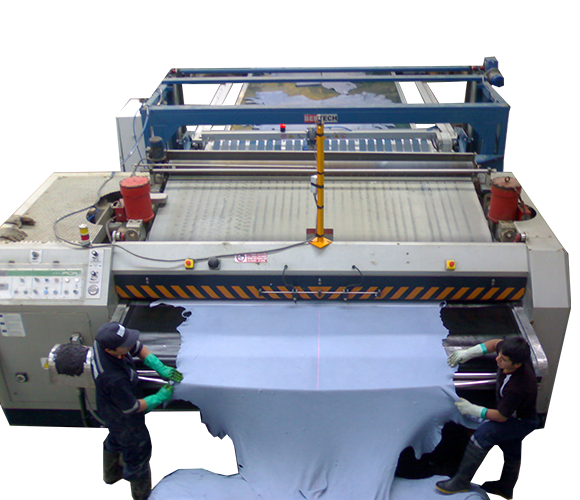

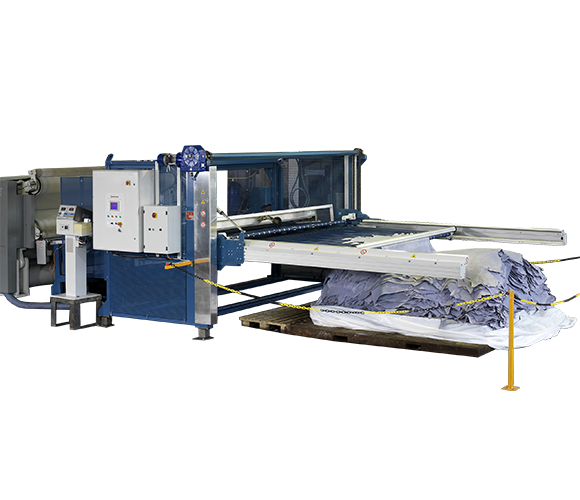

The stacker BERTECH model DYNAMIC is made in two versions: one for the wet end and one for the finishing department.

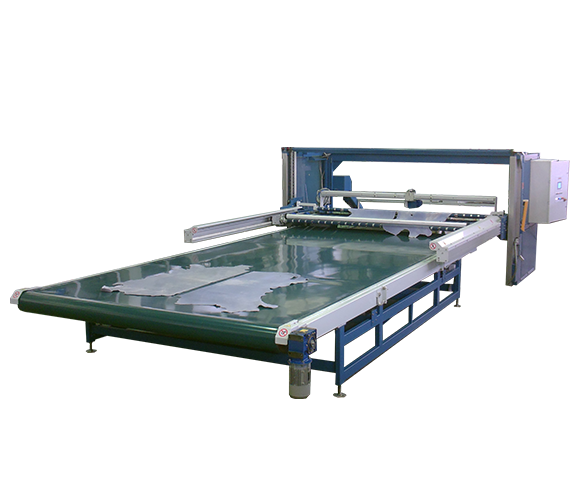

Made of high quality materials, it has a solid frame composed by element tested for the use in tannery. Its reduced dimensions place this stacker among the shortest of its category although the inclination of the fixed conveyor makes it suitable for any type of leather because of the absence of problems related to the sliding or rolling of leathers. BERTECH is the sole manufacturer that equips its stackers DYNAMIC and ARMLESS of the anti-fall system of the lifting device considering it essential for the safety of the machine and operators. Another important characteristic is the working width that is always identical or higher than the one indicated in the leaflet.

The stacker DYNAMIC can easily deposit any kind of leathers:

- On pallet after wet blue press or through feed sammying machine;

- On horse or table after staking machine in crust;

- On horse or table after manual or continuous stucco table;

- On pallet or table after buffing/dedusting line;

- On horse after spray line but even on table when processing firm leathers;

- On horse after ironing/embossing machine but even on table when processing firm leathers;

The DYNAMIC is available in 5 versions:

- XS= extra-short: for sheep & goat (stroke of carriage 1600 mm)

- S= short: to deposit the leathers on horse or table (stroke of carriage 2000 mm)

- M= medium: to deposit on horse, table or pallet short leathers (stroke of carriage 2800 mm)

- L= long: to deposit any kind of leather on any support (stroke of carriage 3100 mm)

- XL= extra-long: for leathers beyond 55 feet on any support (stroke of carriage 3300 mm)