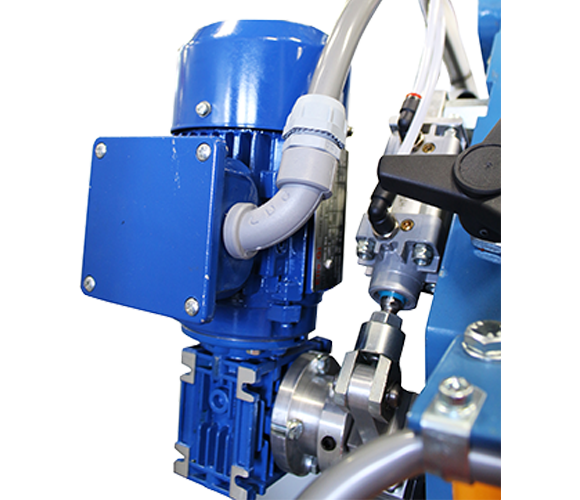

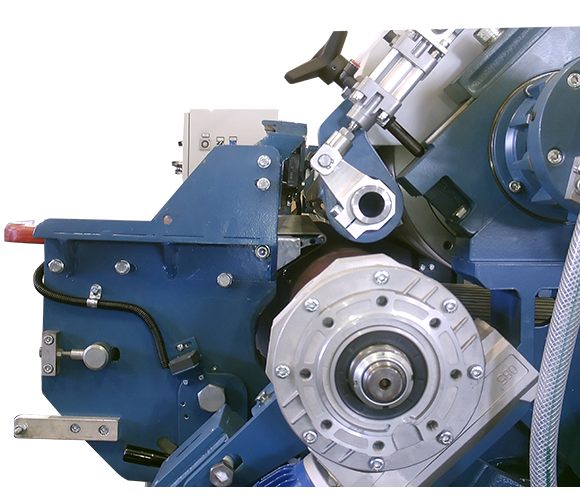

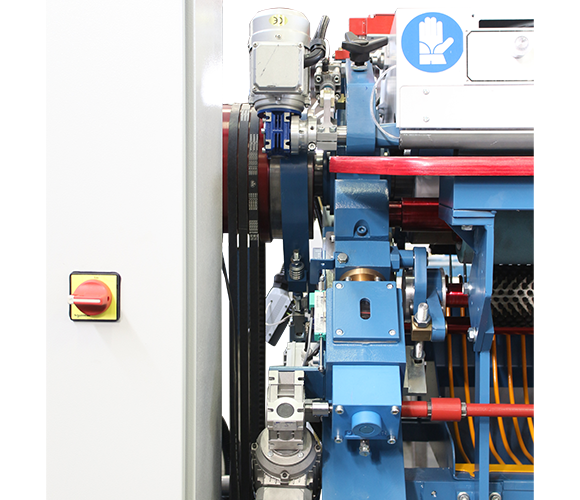

Through-feed belt buffing machine. Designed for articles that require a cold processing and a high efficiency dust discharging; then is suitable to process vegetable tanned leathers, hot and cold greased leathers, stuccoed splits for automotive and reel material (rubber, PU, PVC and similar).

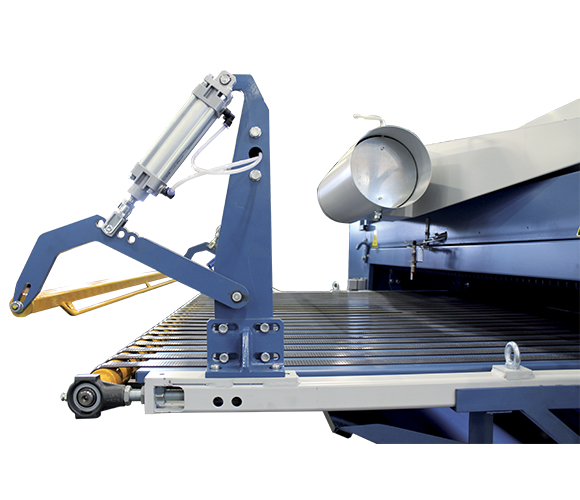

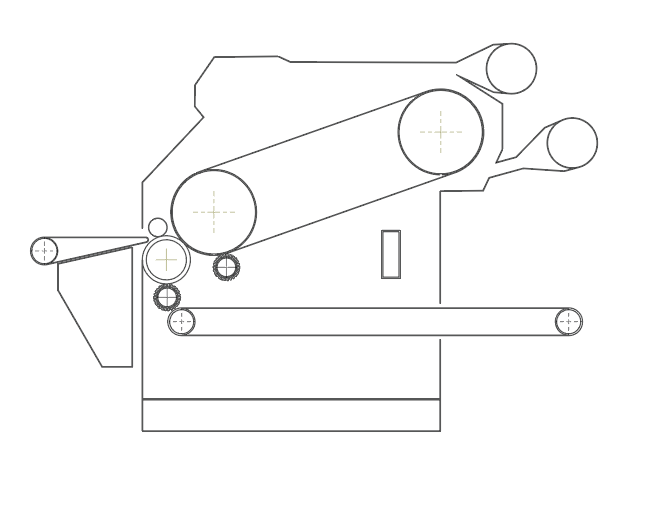

The distance between the buffing point and the exit belt is halved compared to a traditional buffing machine, ensuring the leather is laid out more flatly at the entrance of the dedusting machine.