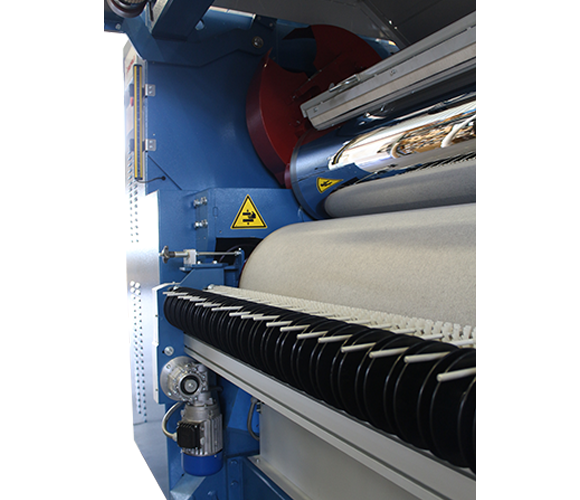

Through-feed press made for ironing, sandblasting and light embossing. It has an automatic roller changing system with revolver device and an independent heating unit for each roller. It can store up to 3 large diameter operative rollers.

The Starlux can be supplied in a single version, double one or all three together.

The Starlux has the automatic roller changing system. Changing the rollers is very easy and fast.

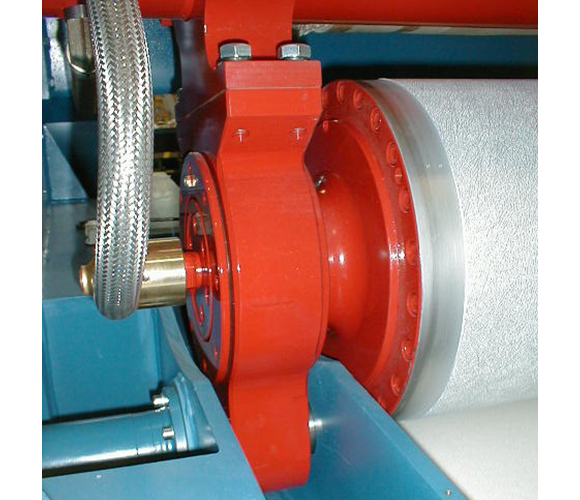

Each roller has its own thermal-oil heating unit for the independent management of the working temperatures. This system permits to change the operative roller many times a day without losses of time. The operative rollers have an internal oil distribution system unique in its genre and the maximum difference of temperature all along the surface of the roller is one degree (1°C). The Starlux can be supplied with one roller and the other two can be supplied separately thanks to the stability of the revolver roller changing system.

In conclusion the Starlux is the ideal machine to iron with pressure any kind of leather and soft leathers without compacting them, to process waxed leathers without changing their colours, to give an excellent glazing effect on the tops of the embossed leathers or to shine the tops of the milled leathers.