NEWS

Having already sold over 400 units worldwide, Bergi can confidently claim that their Superpress T was possibly the world’s best-selling ironing embossing machine. Using this as the benchmark and through long working experience, the new Supervario T aims to keep the main qualitative characteristics whilst improving consistency, productivity and operator safety.

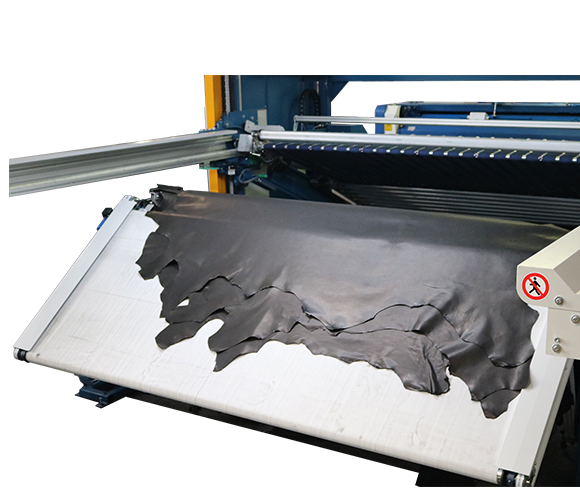

Supervario T: ironing and embossing machine

The Supervario T, extensively remodelled from the basis of the Superpress T is a through feed ironing and embossing machine aimed at upholstery and automotive leather manufacture. Although classinc in its design, with vertically orientated rollers, many important improvements have been effected. Yhe most important improvement is seen with the extent to which contact is made at the nip point between the rollers.

.. There is a 33% increase

Bergi claim that there is a 33% increase in contact where the rollers meet. In tests carried out comparing the Superpress T and the Supervario T, using felts of near identical shore hardness and counter pressure rollers with only 100mm diameter difference using a pressure of 100kg/linear cm, the width of the embossing print form the Supervario was measured at 48mm – in contrast, the Superpress only returned an embossing print of 36mm.

Productivity is improved through an enlarged embossing area and pre-heating of the hides prior to embossing allows for faster throughput as heat transfer from pressure rollers to the hides is improved. Interaction between the machine and operator also see improvements in all aspects of use, safety and maintenance, with ergonomic feed table for better working position, improved temperature control utilising a new triple temperature control system and easier felt changing due to the extractable heating system allowing better access with additional benefit in reducing the felt changing time. Along with changes to the standard machine, many optional accessories are available.

These include a roller storage system for more than six rollers, connecting beams allowing the interchange of the operating rollers between two or three Supervario. Superpress or Superseven machines plus devices for reducing electrostatic charges, detaching the leather from the rollers for combined use with an automated staker and also a metal detector to alert the operatives should metal objects become introduced to the spreader.

Speaking to World Leather, Bergi Presidente Mauro Bergozza said:

The global virtues of a machine are not only given by the quantity and quality of the processed letahers, but also by ease of use. Bergi Company deeply wanted to create a user-friendly machine, a machine closely interacting with the operator to make working life easier and more confortable. In this regard, Bergi adopted all those technological solutions that give the operator the chance to control all the parameters of the machine at a glance. The big touch screen control panel, with its icons, is easy to read and understand allowing constant monitoring of the production, the cameras allow the control of the important areas of the machine, while the lighting system of the surrounding area gives the operators the possibility to move in an illumited and consequently safer work-zone.

Finally, the internet connection allows the ability to monitor and keep under control the general status of the machine and to prevent any inconvenience to both the tannery workers and Bergi staff.

Dopo diversi anni di ricerca, il team Bergi ha finalmente ideato un’innovativa smerigliatrice per pelli morbide, in grado di sopperire […]

In origine dopo le lavorazioni in continuo in conceria, le pelli si prendevano a mano e si mettevano a bancale, […]

L’azienda leader nella progettazione e costruzione di macchine per la lavorazione della pelle completa la gamma delle tecnologie evolute nel […]